Unlocking Power Of Iot Solutions Iot Sensors To Improve Factory

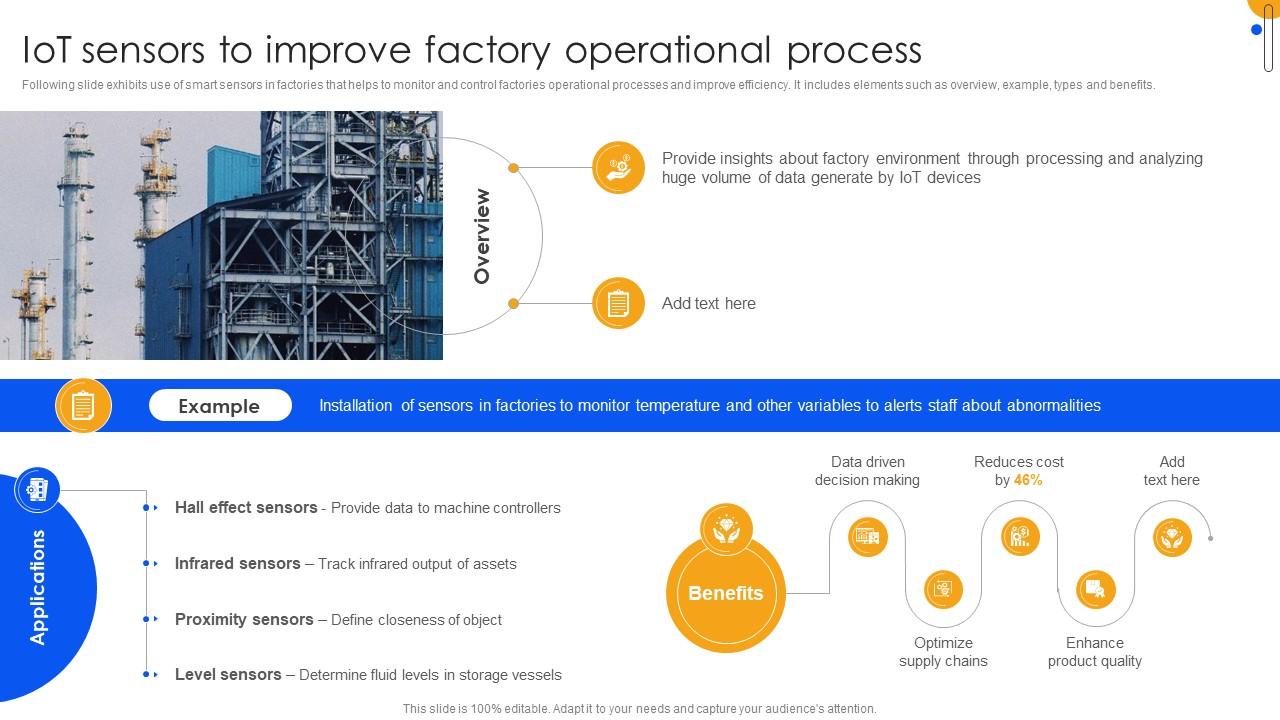

Unlocking Power Of Iot Solutions Iot Sensors To Improve Factory Iot sensors can collect data on product usage and demand, enabling factory managers to predict when certain items will need to be restocked. iot sensors can monitor the conditions of the inventory, such as temperature and humidity, to ensure that they are stored in optimal conditions. With the help of cutting edge iot solutions, manufacturers can now streamline their operations, increase productivity, reduce costs, and enhance overall quality. so, get ready to unlock the full potential of smart factory iot and revolutionize your manufacturing processes. let’s dive in!.

Unlocking Power Of Iot Solutions Overview Of Smart Factory Industrial Connected manufacturing iot sensors enable machines to communicate with each other, share data, and coordinate their activities autonomously. by sharing data between machines, iot devices improve robotic efficiency and productivity while also improving safety and reducing unscheduled maintenance. Their comprehensive suite of iot solutions encompasses sensor integration, data analytics, and machine learning algorithms, enabling manufacturers to unlock the full potential of industry. ⚡discover the benefits of industrial iot (iiot) in manufacturing. ☑️ learn how iiot improves efficiency, reduces downtime, and enables predictive maintenance. ⭐ explore real world examples of iot in manufacturing and how connected devices drive productivity. Iot enabled sensors monitor the printing process in real time, tracking parameters like material usage, print quality, and system health to ensure optimal printing results.

Unlocking Power Of Iot Solutions Iot Solutions Potential For ⚡discover the benefits of industrial iot (iiot) in manufacturing. ☑️ learn how iiot improves efficiency, reduces downtime, and enables predictive maintenance. ⭐ explore real world examples of iot in manufacturing and how connected devices drive productivity. Iot enabled sensors monitor the printing process in real time, tracking parameters like material usage, print quality, and system health to ensure optimal printing results. Iot sensors, coupled with ai analytics, deliver granular, real time visibility into every stage of production. this enables rapid identification and resolution of bottlenecks, quality issues, or process deviations before they impact output. Dalshiiot’s iot sensors are the backbone of industry 4.0. these sensors collect real time data from machines and equipment, enabling factory owners to monitor performance, detect anomalies, and optimize maintenance schedules. by leveraging iot, factory owners can reduce downtime and enhance overall equipment effectiveness. The future of iot and smart factories is poised for exponential transformation as cutting edge technologies converge to drive unprecedented innovation. **5g connectivity** is unlocking ultrafast data transmission with near zero latency, enabling real time communication between iot enabled systems. Managers can drill down and accessworker productivity and safety scores as well as easily track resource and equipment utilization. the result: sensyon smart factories provides complete visibility of what is happening across your entire network of connected devices and sensors on the factory floor.

Comments are closed.