The Differences Between Mig And Tig Welding

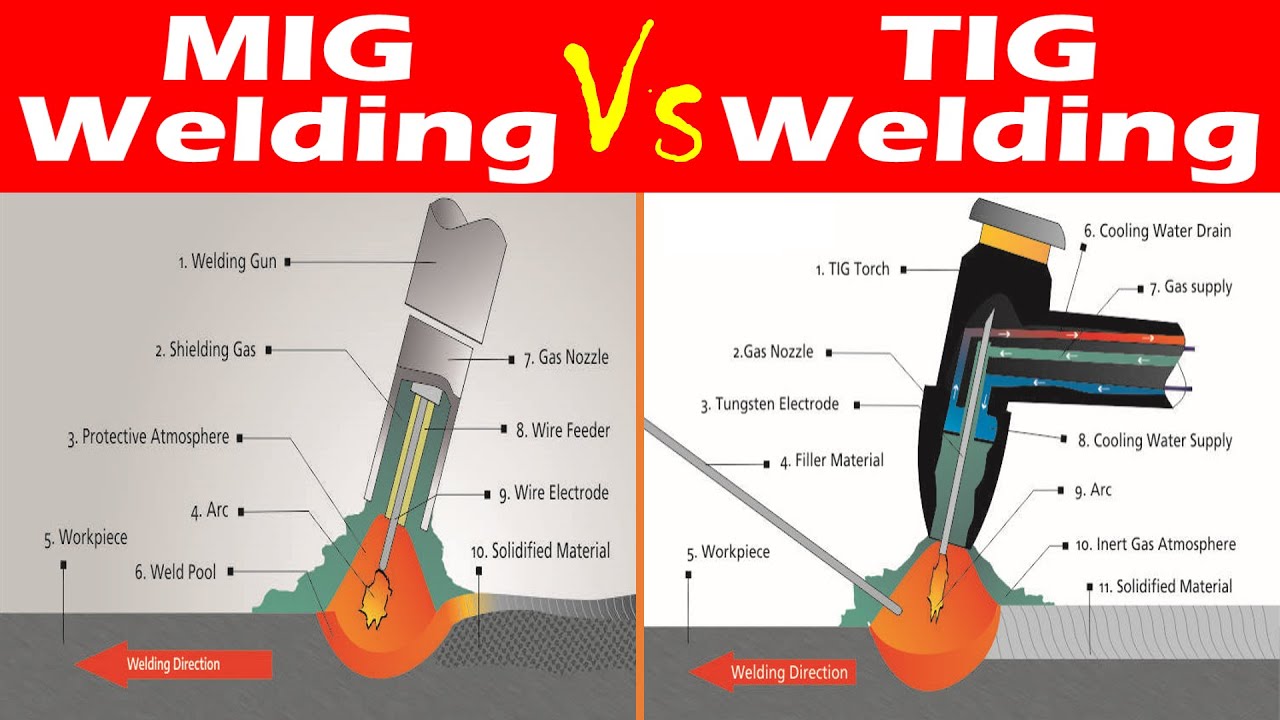

Mig Vs Tig Welding Custom Fabricators Inc Understanding the difference between mig and tig welding is key to the success of any project, and that’s what beginner welders in particular can learn from this article. The difference between tig and mig welding is that mig uses continuous feeding wire, and tig uses welding rods that slowly feed them into the welding place. both tig and mig welding uses an electric arc to make the weld.

What Are The Key Differences Between Tig And Mig Welding Pdf The difference between tig (tungsten inert gas) and mig (metal inert gas) welding is that tig welding uses a tungsten metal rod to fuse two metals directly together, while mig welding uses a feed wire through a spool gun to weld two metals together. The main difference between mig and tig welding is the electrode they use to create the arc. mig uses a consumable solid wire that is machine fed to the weld, whereas tig welding uses a non consumable electrode. The basic difference between mig and tig welding is that one uses a consumable wire electrode (mig) and the other (tig) uses a non consumable tungsten electrode. in the mig welding process, an electric arc is produced between consumable wire electrodes and workpiece metals. This guide explains the difference between mig welding and tig welding. find out when to use tig vs mig welding method and what are the pros and cons.

Mig Vs Tig Welding Types Materials And Applications A 54 Off The basic difference between mig and tig welding is that one uses a consumable wire electrode (mig) and the other (tig) uses a non consumable tungsten electrode. in the mig welding process, an electric arc is produced between consumable wire electrodes and workpiece metals. This guide explains the difference between mig welding and tig welding. find out when to use tig vs mig welding method and what are the pros and cons. However, there are a number of differences between the two processes, including with the welding electrodes used to create the arc. mig uses a solid wire that is machine fed to the weld area while tig uses a non consumable electrode and a hand held filler rod to form the weld. Mig welding is a gas shielded metal arc welding, where, the shielding gas protects the weld pool from the atmospheric contamination. tig welding is a gas shielded tungsten arc welding. mig welding is suitable for homogeneous welding process. tig welding is suitable for autogenous welding process. Mig (metal inert gas) and tig (tungsten inert gas) welding are two popular mig and tig welding processes. mig uses a wire feed to automatically supply the filler material, while tig uses a non consumable tungsten electrode to create the weld. Mig welding uses a continuous wire feed, while tig welding employs a long welding rod. mig (metal inert gas) is faster; tig (tungsten inert gas) allows for greater precision. understanding the differences between mig and tig welding is essential for professionals working with metals.

Mig Vs Tig Welding Types Materials And Applications A 44 Off However, there are a number of differences between the two processes, including with the welding electrodes used to create the arc. mig uses a solid wire that is machine fed to the weld area while tig uses a non consumable electrode and a hand held filler rod to form the weld. Mig welding is a gas shielded metal arc welding, where, the shielding gas protects the weld pool from the atmospheric contamination. tig welding is a gas shielded tungsten arc welding. mig welding is suitable for homogeneous welding process. tig welding is suitable for autogenous welding process. Mig (metal inert gas) and tig (tungsten inert gas) welding are two popular mig and tig welding processes. mig uses a wire feed to automatically supply the filler material, while tig uses a non consumable tungsten electrode to create the weld. Mig welding uses a continuous wire feed, while tig welding employs a long welding rod. mig (metal inert gas) is faster; tig (tungsten inert gas) allows for greater precision. understanding the differences between mig and tig welding is essential for professionals working with metals.

The Difference Between Mig Tig Welding Mig (metal inert gas) and tig (tungsten inert gas) welding are two popular mig and tig welding processes. mig uses a wire feed to automatically supply the filler material, while tig uses a non consumable tungsten electrode to create the weld. Mig welding uses a continuous wire feed, while tig welding employs a long welding rod. mig (metal inert gas) is faster; tig (tungsten inert gas) allows for greater precision. understanding the differences between mig and tig welding is essential for professionals working with metals.

Comments are closed.