Modeling Welds For Finite Element Analysis Fea Apollo Engineering

Modeling Welds For Finite Element Analysis Fea Apollo Engineering This article is meant to explain the method we use at apollo engineering design group to model and predict stress in a weld using the hot spot method. we will then explore a few different options that one might choose to model welds and compare to the results obtained using the hot spot method. Check the article "modeling welds for finite element analysis (fea)" on the apollo engineering blog. it compares different approaches to weld modeling and their accuracy. the choice of the simplification level and the location of stress probing also depend on the method used for fatigue evaluation.

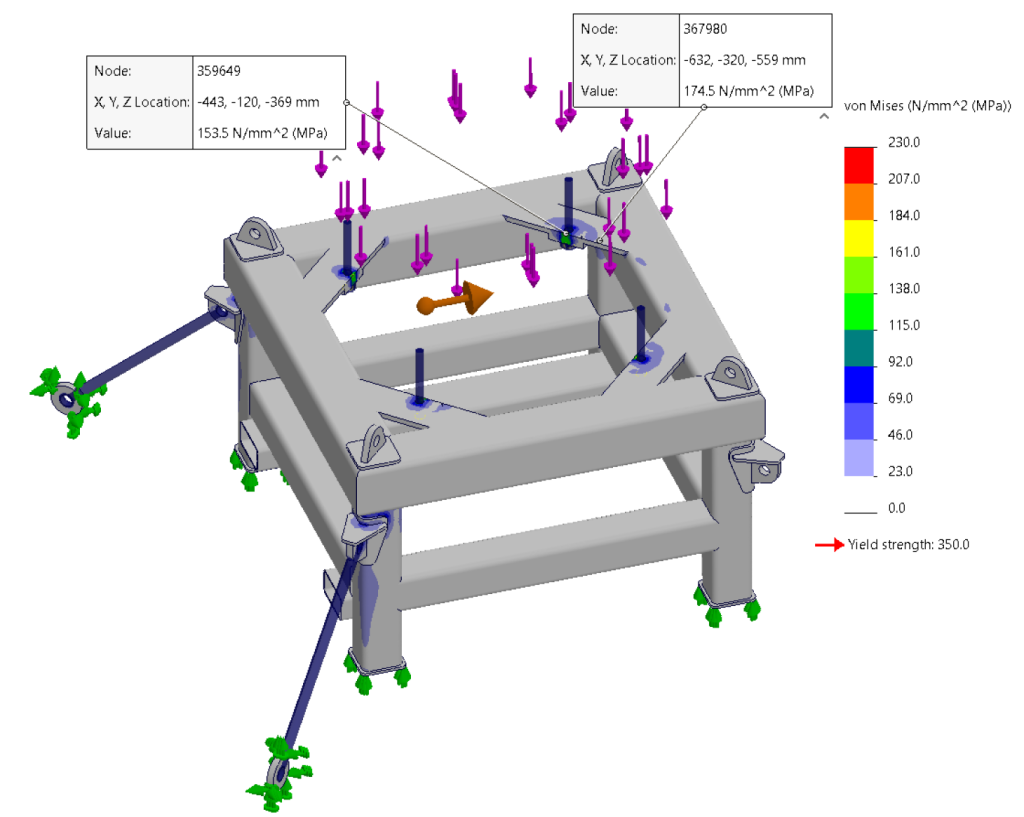

Fea Finite Element Analysis Dynamic Engineering Consultants Perth The document discusses different methods for modeling welds in finite element analysis (fea) simulations. it explains that welds can be modeled using solid elements, beam elements, or spring dashpot elements, with each method having pros and cons. Finite element analysis (fea) has become a practical method of predicting stresses and deflection for loaded structures. fea accurately identifies the load path, which can be difficult using classical analysis with complex structures. This work deals with the simulation of fusion welding by the finite element method. the implemented models include a moving heat source, temperature dependence of thermo physical properties, elasto plasticity, non steady state heat transfer, and mechanical analysis. In this post, we want to present a streamlined process for weld analysis using fea (specifically ansys workbench) as the primary tool. we will focus on how to properly size fillet welds, a skill which has proven particularly useful for complex weldments.

Modeling Welds For Finite Element Analysis Fea Apollo Engineering This work deals with the simulation of fusion welding by the finite element method. the implemented models include a moving heat source, temperature dependence of thermo physical properties, elasto plasticity, non steady state heat transfer, and mechanical analysis. In this post, we want to present a streamlined process for weld analysis using fea (specifically ansys workbench) as the primary tool. we will focus on how to properly size fillet welds, a skill which has proven particularly useful for complex weldments. Heat transfer finite element model using ansys and hyper extrude software to simulate the thermal distribution during the fsw of aa6061 t6. besides that, yad wanshi, bag, and pal (2014) have developed a 3d heat flow numerical model to predict the heat generated. The way i analyze welds with fea is to extract reactions at the joint and take them into a spreadsheet, where i calculate weld stresses and allowables according to what ever code i am using. How often have you been faced with the task of performing finite element analysis (fea) on a welded component? have you wondered how to properly model welds in that analysis?. I am looking for information regarding welding simulation using fea. let me be very clear as to what i desire. i want to know what methodologies have been developed and employed that can properly simulate the thermo mechanical aspects of welding (both spot and arc welding) on the structure.

Modeling Welds For Finite Element Analysis Fea Apollo Engineering Heat transfer finite element model using ansys and hyper extrude software to simulate the thermal distribution during the fsw of aa6061 t6. besides that, yad wanshi, bag, and pal (2014) have developed a 3d heat flow numerical model to predict the heat generated. The way i analyze welds with fea is to extract reactions at the joint and take them into a spreadsheet, where i calculate weld stresses and allowables according to what ever code i am using. How often have you been faced with the task of performing finite element analysis (fea) on a welded component? have you wondered how to properly model welds in that analysis?. I am looking for information regarding welding simulation using fea. let me be very clear as to what i desire. i want to know what methodologies have been developed and employed that can properly simulate the thermo mechanical aspects of welding (both spot and arc welding) on the structure.

Modeling Welds For Finite Element Analysis Fea Apollo Engineering How often have you been faced with the task of performing finite element analysis (fea) on a welded component? have you wondered how to properly model welds in that analysis?. I am looking for information regarding welding simulation using fea. let me be very clear as to what i desire. i want to know what methodologies have been developed and employed that can properly simulate the thermo mechanical aspects of welding (both spot and arc welding) on the structure.

Comments are closed.