Milling Machine Operation Types And Parts Of Milling Vrogue Co

Milling Machine Definition Parts Types Operations With Pdf Pdf Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy duty gang milling operations. it is one of the most commonly used processes for machining custom parts to precise tolerances. Milling is the process of machining using rotating cutters to remove material by advancing a cutter into a workpiece. milling covers a wide variety of different operations and machines, from small individual parts to large, heavy duty group milling operations.

Milling Machine Operations Pdf Machining Gear Milling is machining that involves the removal of material from a metal workpiece using a rotary cutting tool. learn more about it here. Milling is a popular machining process. milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner. this method of subtractive manufacturing seeks to give the workpiece the desired shape. Milling machine definition: the milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint cutter. the metal removal rate is higher very high as the cutter has a high speed and many cutting edges. Milling is the process of using a rotating cutter to remove material from a workpiece. the cutter can be moved in different directions, allowing for precise cutting and shaping of various materials.

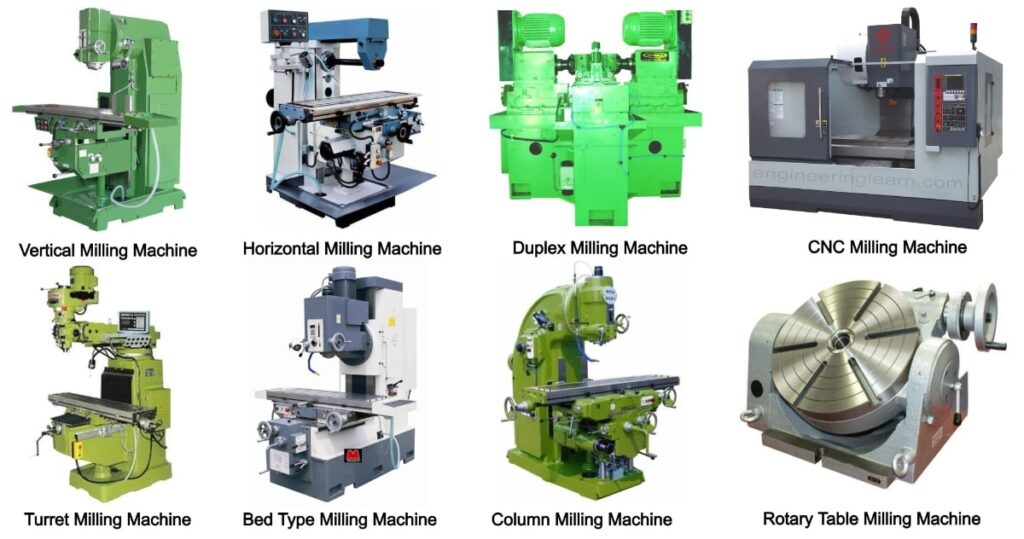

Milling Machine Operation Types And Parts Of Milling 41 Off Milling machine definition: the milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint cutter. the metal removal rate is higher very high as the cutter has a high speed and many cutting edges. Milling is the process of using a rotating cutter to remove material from a workpiece. the cutter can be moved in different directions, allowing for precise cutting and shaping of various materials. Milling is a type of machining process that uses a rotating cutting tool to remove material from a workpiece. milling can create a variety of shapes and features on a part, such as slots, holes, pockets, and contours. Milling is a machining process that removes material from a workpiece using a rotating cutting tool called a milling cutter. it is widely used in manufacturing to shape and create parts from various materials, including metal, plastic, wood, and composites. Milling operations are fast becoming a necessity in the manufacturing world. from transforming raw materials into desired shapes, milling operation plays a fundamental role in modern applications – including aerospace and automotive industry. what is a milling operation?. Milling is a substractive machining process that uses many machine toolsets to efficiently precision cut a variety of materials (such as metals, plastics, or wood) into a defined geometrical part.

Comments are closed.