Mig Vs Tig Welding Types Materials And Applications

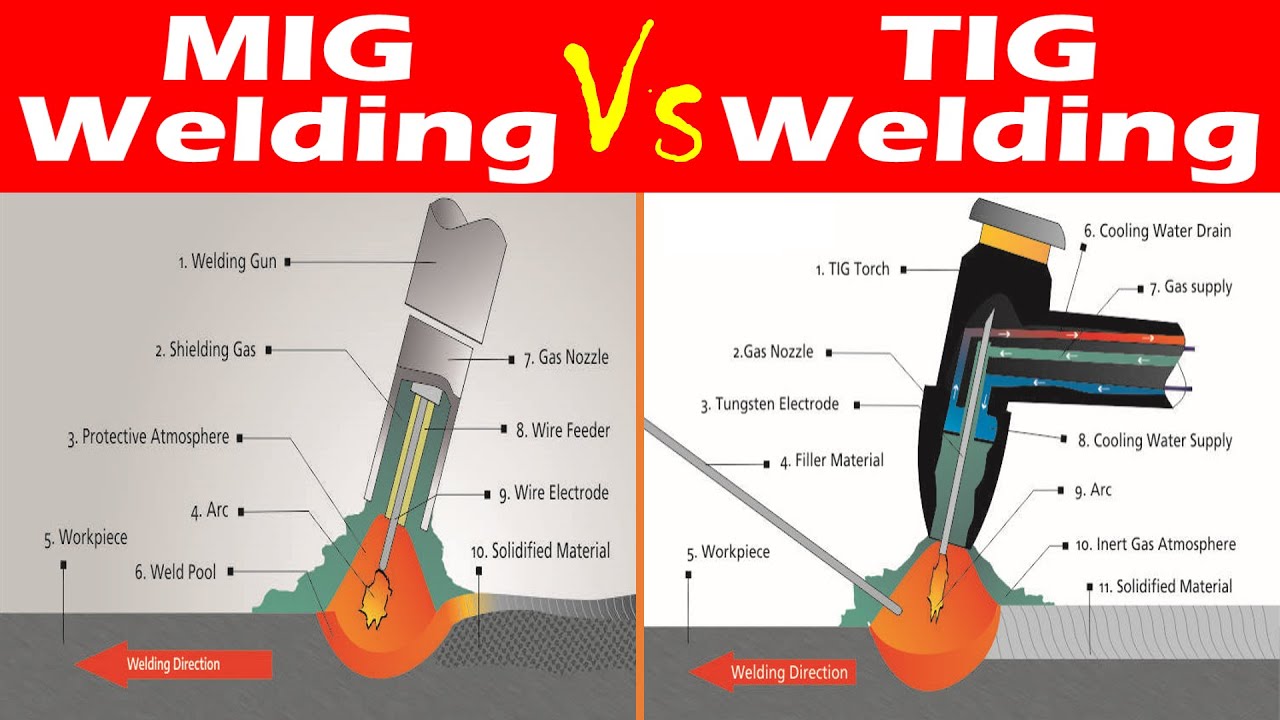

Mig Vs Tig Welding Custom Fabricators Inc Discover the differences between mig and tig welding techniques, explore various types, suitable materials, and applications. get expert insights on choosing the right welding method for your project. Though both utilize an inert shielding gas and externally supplied filler material to join base metals, mig and tig welding differ in key application areas such as workpiece thickness capabilities, quality of welds produced, and operator skill requirements.

Mig Vs Tig Welding Types Materials And Applications A 54 Off In this guide, we’ll break down everything you need to know about mig vs tig welding, including their differences, strengths, limitations, and the types of materials and applications they’re best suited for. The difference between tig and mig welding is that mig uses continuous feeding wire, and tig uses welding rods that slowly feed them into the welding place. both tig and mig welding uses an electric arc to make the weld. In this post, we’ll compare mig and tig welding, two of the most widely used welding processes. you'll learn about their principles, pros and cons, and when to use each method. whether you're a beginner or an experienced welder, this guide will help you make the right choice for your project. what is mig welding?. Mig welding works faster and suits thick metals, making it great for big projects and beginners. tig welding offers more control and cleaner welds, ideal for thin metals and precise jobs.

Mig Vs Tig Welding Types Materials And Applications A 44 Off In this post, we’ll compare mig and tig welding, two of the most widely used welding processes. you'll learn about their principles, pros and cons, and when to use each method. whether you're a beginner or an experienced welder, this guide will help you make the right choice for your project. what is mig welding?. Mig welding works faster and suits thick metals, making it great for big projects and beginners. tig welding offers more control and cleaner welds, ideal for thin metals and precise jobs. Mig welding is faster and more accessible, ideal for thick materials and large scale production. in contrast, tig welding provides higher precision and cleaner welds, making it the best choice for delicate and aesthetically critical projects. Material types: use mig welding for carbon steel and thick aluminum, and tig welding for thin aluminum, stainless steel, and exotic metals. precision work: tig welding is the go to method for applications requiring high precision and aesthetic quality. Mig (metal inert gas) and tig (tungsten inert gas) welding are two popular mig and tig welding processes. mig uses a wire feed to automatically supply the filler material, while tig uses a non consumable tungsten electrode to create the weld. mig operates at higher speeds, making it suitable for thicker materials and faster production. Both mig and tig welding create a weld by heating a metal surface with an electric arc. the difference lies in how the arc is used to join the metal surfaces. mig welding uses consumable rods, also known as consumable electrode fillers, that the arc melts to produce a weld.

Comments are closed.