Fillable Online 4 Types Of Welding Explained Mig Vs Tig Vs Stick Vs

Mig Vs Tig Welding Custom Fabricators Inc Discover the key differences between mig, tig, stick, and flux core welding. learn which method suits your project best in this concise guid. Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more. draw or type your signature, upload a signature image, or capture it with your digital camera. email, fax, or share your 4 types of welding form via url.

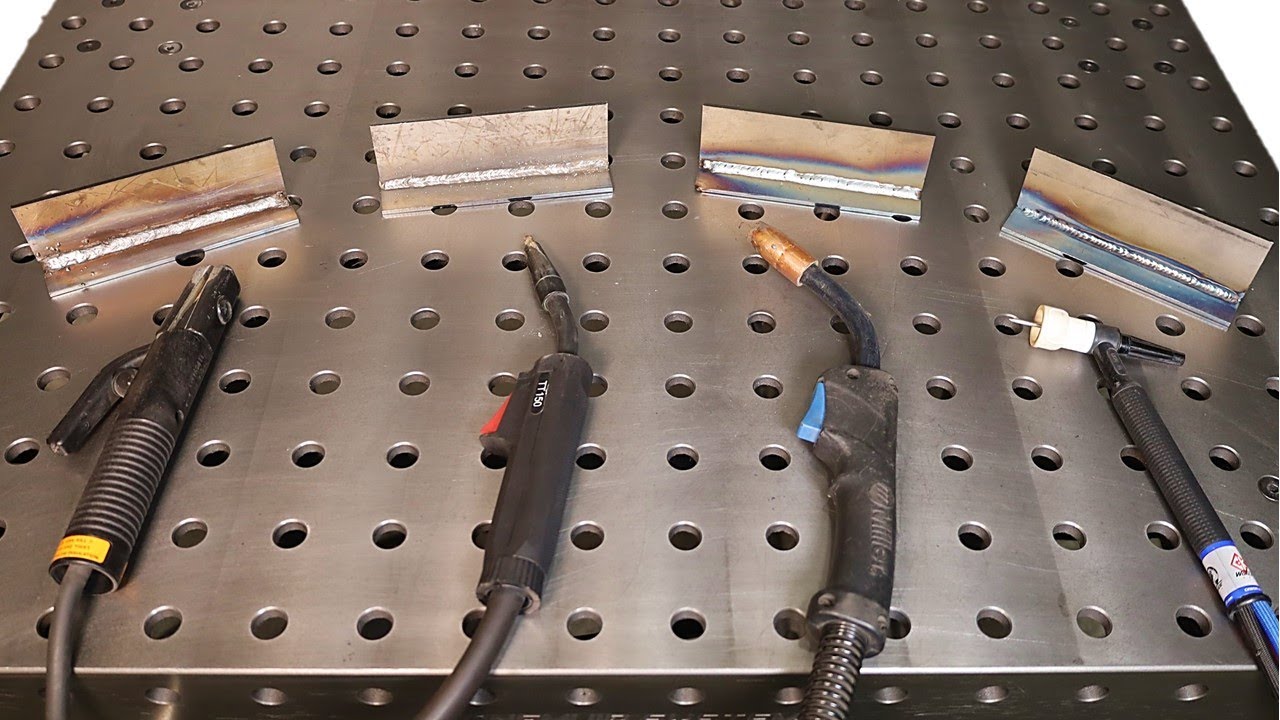

4 Types Of Welding Explained Mig Vs Tig Vs Stick Vs Chords The four standard welding processes used in most manual welding applications are mig, tig, stick, and flux cored arc welding. in this article, you’ll learn about their advantages and disadvantages, and what kind of work each is meant for. Below, i’ll take a look at the three most common welding methods – mig, tig, and stick – to see how they compare against each other. at a most basic level, welding is passing a current through an electrode and melting a filler material into a groove or area to seal it so that two pieces of metal become one. There are four main types: mig, tig, stick, and flux. each has its own way of working and special features. in this article, we'll explore these different welding styles. mig welding gun is fast and flexible, great for many projects. tig welding is all about detail and clean results. stick welding is easy to learn and really strong. Generally speaking, tig is more suitable for clean, intricate welds where appearance is paramount ahead of efficiency. mig is a much easier process but the results aren’t quite to the same standard as tig. stick is useful for welding rusty metal or welding outside on the farm.

4 Types Of Welding Explained Mig Vs Tig Vs Stick Vs Flux Core There are four main types: mig, tig, stick, and flux. each has its own way of working and special features. in this article, we'll explore these different welding styles. mig welding gun is fast and flexible, great for many projects. tig welding is all about detail and clean results. stick welding is easy to learn and really strong. Generally speaking, tig is more suitable for clean, intricate welds where appearance is paramount ahead of efficiency. mig is a much easier process but the results aren’t quite to the same standard as tig. stick is useful for welding rusty metal or welding outside on the farm. Here’s a comparison of four popular welding methods—mig (metal inert gas), tig (tungsten inert gas), stick (shielded metal arc welding, smaw), and flux core welding—highlighting their key features, advantages, and typical applications:. In the world of welding, there are several different processes to choose from, each with its own advantages and disadvantages. this article will explore four popular welding methods: mig (metal inert gas), tig (tungsten inert gas), stick, and flux core. A tig welder delivers precision, while a mig welder offers speed and ease. stick welders excel outdoors, and flux core wire boosts productivity without shielding gas. Mig welding uses a continuous wire feed and is suitable for thin or thick materials. tig welding offers high precision, whereas stick welding is versatile and works well outdoors. mastering various welding techniques can significantly enhance fabrication quality and efficiency.

Fillable Online 4 Types Of Welding Explained Mig Vs Tig Vs Stick Vs Here’s a comparison of four popular welding methods—mig (metal inert gas), tig (tungsten inert gas), stick (shielded metal arc welding, smaw), and flux core welding—highlighting their key features, advantages, and typical applications:. In the world of welding, there are several different processes to choose from, each with its own advantages and disadvantages. this article will explore four popular welding methods: mig (metal inert gas), tig (tungsten inert gas), stick, and flux core. A tig welder delivers precision, while a mig welder offers speed and ease. stick welders excel outdoors, and flux core wire boosts productivity without shielding gas. Mig welding uses a continuous wire feed and is suitable for thin or thick materials. tig welding offers high precision, whereas stick welding is versatile and works well outdoors. mastering various welding techniques can significantly enhance fabrication quality and efficiency.

Comments are closed.