Difference Between Tig And Mig Welding Pros Cones Weldlover

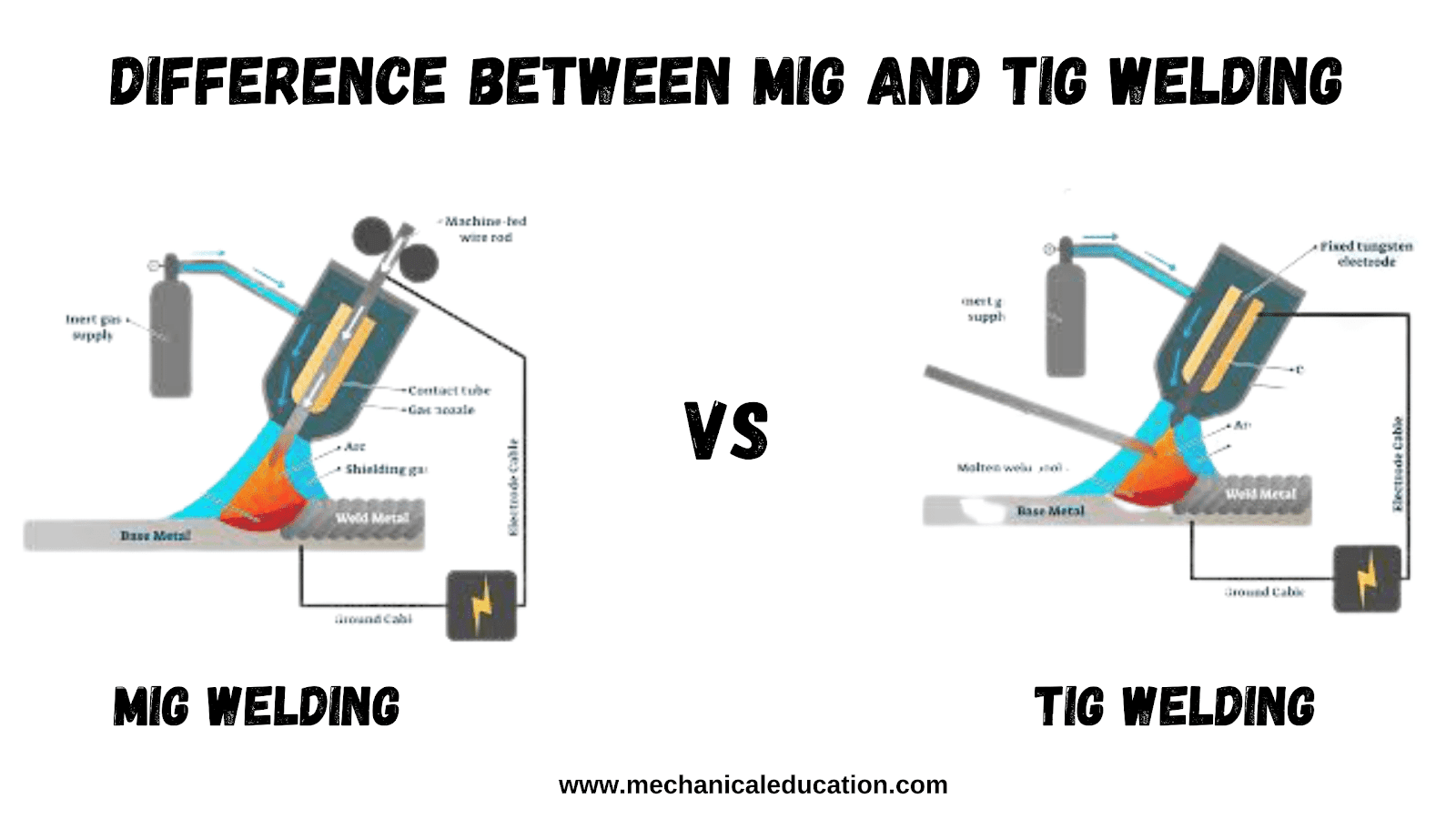

Mig Vs Tig Welding Custom Fabricators Inc The main difference between tig and mig welding is that the electric arc is originated in between a burnable electrode and metal workpiece in mig welding while an electric arc is formed in between a non consumable electrode and base metal in tig welding. This guide explains the difference between mig welding and tig welding. find out when to use tig vs mig welding method and what are the pros and cons.

.webp)

Difference Between Mig And Tig Welding While both are excellent ways of joining metal, the mig vs. tig welding debate will likely continue. they both have their pros and cons, meaning neither one is “better” than the other overall. Learn about the differences between mig and tig welding techniques. understand the advantages and applications of each method in various industries. The difference between tig (tungsten inert gas) and mig (metal inert gas) welding is that tig welding uses a tungsten metal rod to fuse two metals directly together, while mig welding uses a feed wire through a spool gun to weld two metals together. Speed: mig welding is faster than tig welding due to its continuous wire feed. ease of use: this technique is user friendly, even for beginners, as it requires less skill and has a shorter learning curve. versatility: mig welding is versatile and works well on thick materials like mild steel, aluminum, and stainless steel.

Difference Between Tig And Mig Welding Pros Cones Weldlover The difference between tig (tungsten inert gas) and mig (metal inert gas) welding is that tig welding uses a tungsten metal rod to fuse two metals directly together, while mig welding uses a feed wire through a spool gun to weld two metals together. Speed: mig welding is faster than tig welding due to its continuous wire feed. ease of use: this technique is user friendly, even for beginners, as it requires less skill and has a shorter learning curve. versatility: mig welding is versatile and works well on thick materials like mild steel, aluminum, and stainless steel. Choosing between mig and tig welding depends on your specific needs, material types, and project complexity. while mig is great for speed and ease, tig offers the precision and finish required for high quality, professional work. Mig uses a consumable solid wire that is machine fed to the weld, whereas tig welding uses a non consumable electrode. tig welding will often use a hand held filler rod to create the join. a sound understanding of how mig and tig welding work and where they excel will make you a better welder. Tig welding, or tungsten inert gas welding, uses a non consumable tungsten electrode to generate an electric arc. the welder manually feeds a filler rod into the weld puddle while controlling the heat input through a foot pedal. unlike mig, tig welding doesn’t automatically feed filler material. For beginners, choosing between mig vs. tig welding can feel overwhelming. both are popular welding techniques, but they differ in complexity, applications, and learning curves. this article breaks down the key differences, benefits, and challenges of mig and tig welding to help you decide which one to learn first.

Difference Between Mig And Tig Welding Mechanicaleducation Choosing between mig and tig welding depends on your specific needs, material types, and project complexity. while mig is great for speed and ease, tig offers the precision and finish required for high quality, professional work. Mig uses a consumable solid wire that is machine fed to the weld, whereas tig welding uses a non consumable electrode. tig welding will often use a hand held filler rod to create the join. a sound understanding of how mig and tig welding work and where they excel will make you a better welder. Tig welding, or tungsten inert gas welding, uses a non consumable tungsten electrode to generate an electric arc. the welder manually feeds a filler rod into the weld puddle while controlling the heat input through a foot pedal. unlike mig, tig welding doesn’t automatically feed filler material. For beginners, choosing between mig vs. tig welding can feel overwhelming. both are popular welding techniques, but they differ in complexity, applications, and learning curves. this article breaks down the key differences, benefits, and challenges of mig and tig welding to help you decide which one to learn first.

Mig Vs Tig Welding Types Materials And Applications A 44 Off Tig welding, or tungsten inert gas welding, uses a non consumable tungsten electrode to generate an electric arc. the welder manually feeds a filler rod into the weld puddle while controlling the heat input through a foot pedal. unlike mig, tig welding doesn’t automatically feed filler material. For beginners, choosing between mig vs. tig welding can feel overwhelming. both are popular welding techniques, but they differ in complexity, applications, and learning curves. this article breaks down the key differences, benefits, and challenges of mig and tig welding to help you decide which one to learn first.

Comments are closed.