Automation Engineering Efficiency Using Iec 61499

Iec 61499 Reference Model For Distributed Automation Pdf In just 45 minutes you’ll learn: why iec 61499 challenges traditional paradigms to help deliver more effectively. how ecostruxure automation expert build upon iec 61499 to improve engineering efficiency – leveraging external design data to automate control engineering. When executing automation projects we strive to deliver cost effectively and predictably in order to meet the design intents of the plant owner or builder.

Iec 61499 Standard For Distributed Automation Welcome Here are five ways iec 61499 optimizes the creation and management of modern data driven automation systems: black box software components. the event driven function block is the basic building block of iec 61499 and encourages a software component approach to automation applications. The iec 61499 standard sets a foundation for industrial automation application portability that creates wide ranging benefits, including easy it ot system convergence, improved return on investment on software applications that can run independent of any hardware platform, and engineering design efficiency that radically speeds up new product. The remote i o system is1 by german vendor r.stahl can be used with programming tools based on iec 61131 3 or iec 61499, is1 for numerous oem applications and modular automation concepts like mtp. This paper implements the proposal of a syntactic interoperability between the ieee 1451 family of standards and iec 61499 inside a reference architecture model for validation purposes. the results found application in real time data acquisition in industrial automation environments.

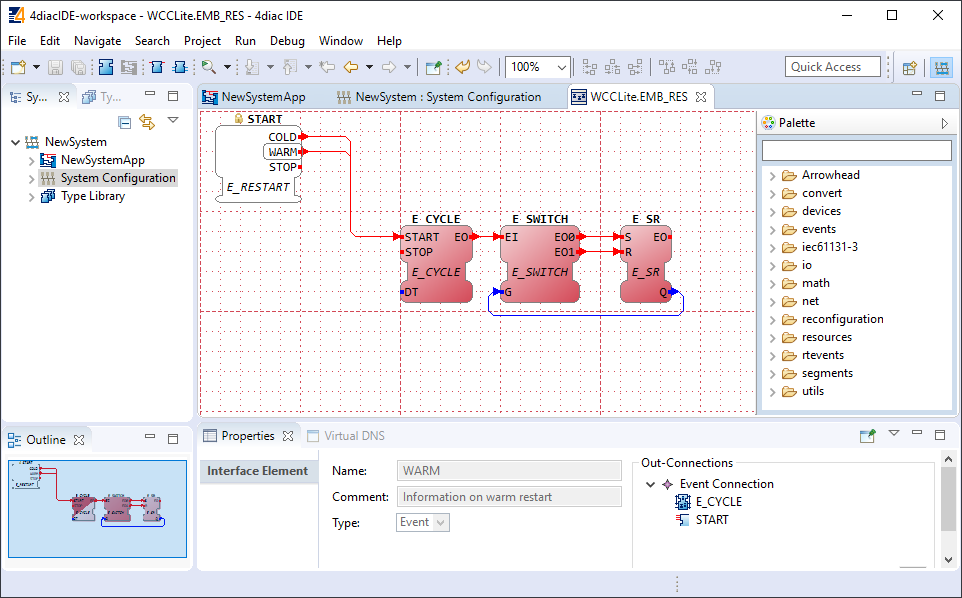

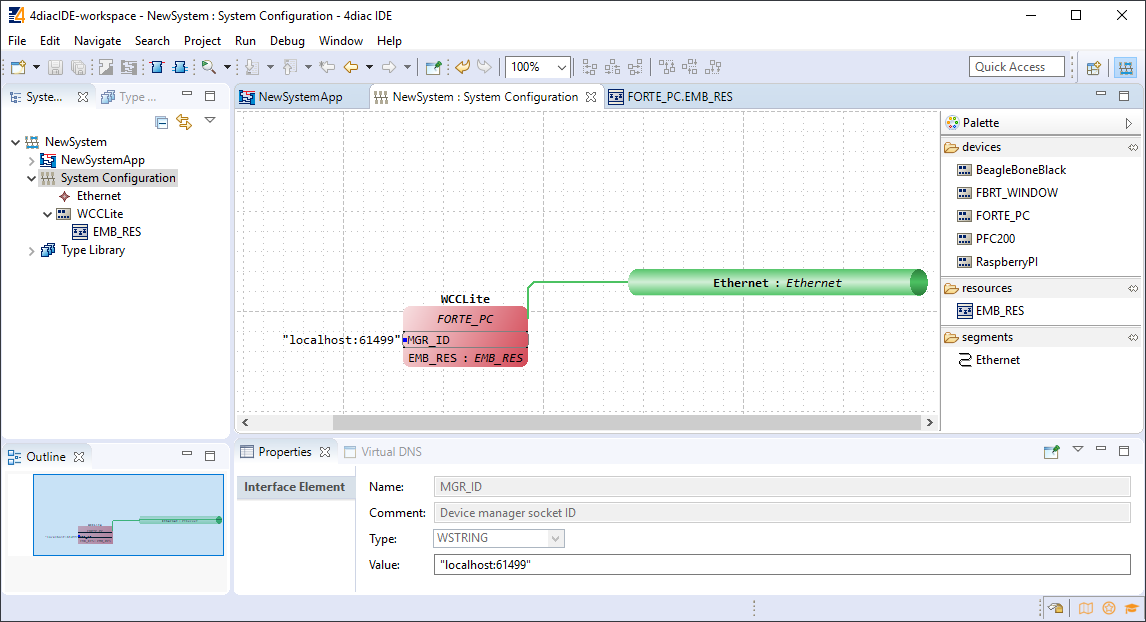

Iec 61499 Iec61499 Info The remote i o system is1 by german vendor r.stahl can be used with programming tools based on iec 61131 3 or iec 61499, is1 for numerous oem applications and modular automation concepts like mtp. This paper implements the proposal of a syntactic interoperability between the ieee 1451 family of standards and iec 61499 inside a reference architecture model for validation purposes. the results found application in real time data acquisition in industrial automation environments. Iec 61499 is an emerging standard for distributed automation which requires well defined design practises to improve development efficiency. in this paper, we extend the one line engineering design pattern and provide step by step guidelines on its implementation keeping in mind key features of industry 4.0. The primary objectives of the poc project were to explore the technical feasibility of an open process automation architecture and to create a system with components from multiple suppliers. existing standards were utilized where possible, including opc ua (2), iec 61131 (3), and iec 61499 (4). figure 3. The long term iec 61499 standardization benefits of lower cost, faster implementation speed, and greater automation system flexibility far outweigh the typical 3 12 month learning curve of an initial project. Iec 61499 – function blocks for distributed control systems sets up a framework for distributed automation that allows you control events and change the system’s setup easily. it makes iec 61131 better by adding support for modular, industry 4.0 based architectures that can work with other systems and move around.

Iec 61499 Iec61499 Info Iec 61499 is an emerging standard for distributed automation which requires well defined design practises to improve development efficiency. in this paper, we extend the one line engineering design pattern and provide step by step guidelines on its implementation keeping in mind key features of industry 4.0. The primary objectives of the poc project were to explore the technical feasibility of an open process automation architecture and to create a system with components from multiple suppliers. existing standards were utilized where possible, including opc ua (2), iec 61131 (3), and iec 61499 (4). figure 3. The long term iec 61499 standardization benefits of lower cost, faster implementation speed, and greater automation system flexibility far outweigh the typical 3 12 month learning curve of an initial project. Iec 61499 – function blocks for distributed control systems sets up a framework for distributed automation that allows you control events and change the system’s setup easily. it makes iec 61131 better by adding support for modular, industry 4.0 based architectures that can work with other systems and move around.

Comments are closed.