7 Common Job Shop Scheduling Challenges How To Solve Them

The Job Shop Scheduling Problem Solved Wth Pdf Genetic Algorithm In this blog post, we’ll take a look at the most common shop floor challenges manufacturers face and explain how job shop scheduling software can help resolve them. Poor scheduling practices—whether caused by last minute schedule changes or misaligned employee schedules—can lead to inefficiencies and unhappy staff. this guide highlights common scheduling problems and provides actionable solutions tailored to australian businesses.

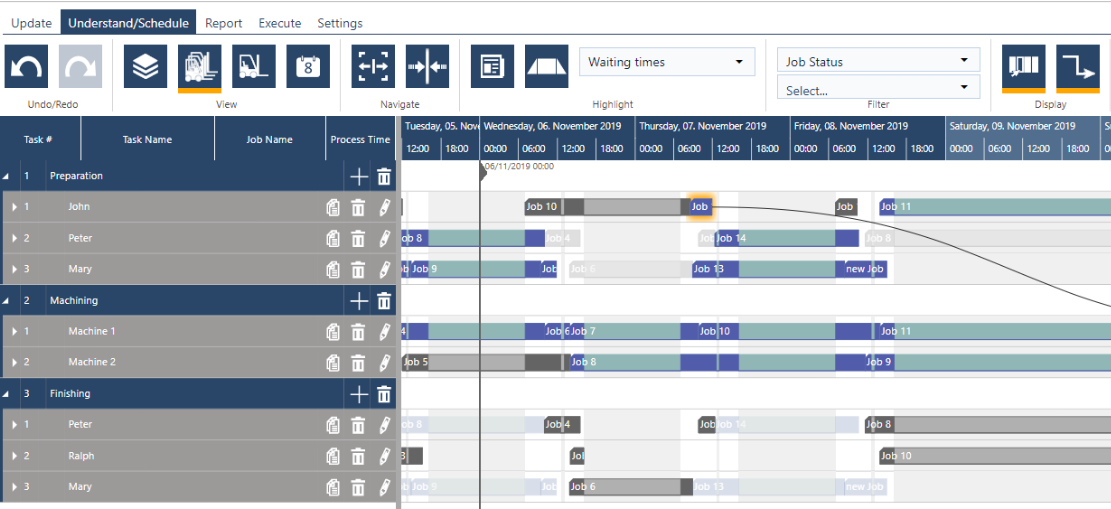

4 Common Job Shop Scheduling Challenges The Visual Scheduling Answer In this blog, we’ll explore the common hurdles faced in job shop manufacturing and actionable strategies to overcome them, focusing on improving workflows, reducing costs, and enhancing productivity. Here are just a few of the common scheduling challenges that cause us to have to continually update the schedule: 1. but there is also no question that scheduling plays a big role in our on time delivery performance and our lead time. In this blog, we will explore the key problems in job shop scheduling, the factors that complicate this process, and the optimization strategies used to achieve efficiency. 1. total processing time. 2. mean flow time. 3. machine idle time. 4. job lateness. 1. number of jobs and machines. 2. manufacturing facility type. 3. job characteristics. 4. Job shop scheduling — high mix low volume job shops and machine shops can be quite a challenge to schedule. why? here are just a few of the complex problems and challenges that plague the.

7 Common Job Shop Scheduling Challenges How To Solve Them In this blog, we will explore the key problems in job shop scheduling, the factors that complicate this process, and the optimization strategies used to achieve efficiency. 1. total processing time. 2. mean flow time. 3. machine idle time. 4. job lateness. 1. number of jobs and machines. 2. manufacturing facility type. 3. job characteristics. 4. Job shop scheduling — high mix low volume job shops and machine shops can be quite a challenge to schedule. why? here are just a few of the complex problems and challenges that plague the. In this article, we will discuss the core challenges of job shop scheduling and how planning solutions, including timefold, can mitigate these challenges to help manufacturers streamline their operations, reduce lead times, and improve overall efficiency. Here are just a few of the common scheduling challenges that cause us to continually update the schedule: 1 1. clients change their mind 2. vendors aren’t always reliable 3. mix can vary wildly and so our constraint move 4. employees do not always have the right skill and their discipline is lacking 5. processes are not reliable 6. Here are five major challenges that i have had to deal with in the past. production job scheduling problems can be extremely complex, with large numbers of variables and constraints. this can make it difficult to formulate an optimization problem that can be solved efficiently. Ready to uncover the key scheduling missteps and how to sidestep them? let’s jump in! 1. poor visibility into shop floor operations. to begin with, one of the biggest mistakes many job shops make is not having real time visibility into what’s happening on the shop floor.

Comments are closed.